Plastic wood can be made into different shapes and sizes according to the applications. For example, plastic wood planks can be used for outdoor flooring, decking, and roof; a plastic wood panel is usually used as an interior or exterior wall panel. But today, what we are going to talk about is the plastic wood that is specially used for upholstering outdoor furniture.

What Is the Plastic Wood For Outdoor Furniture?

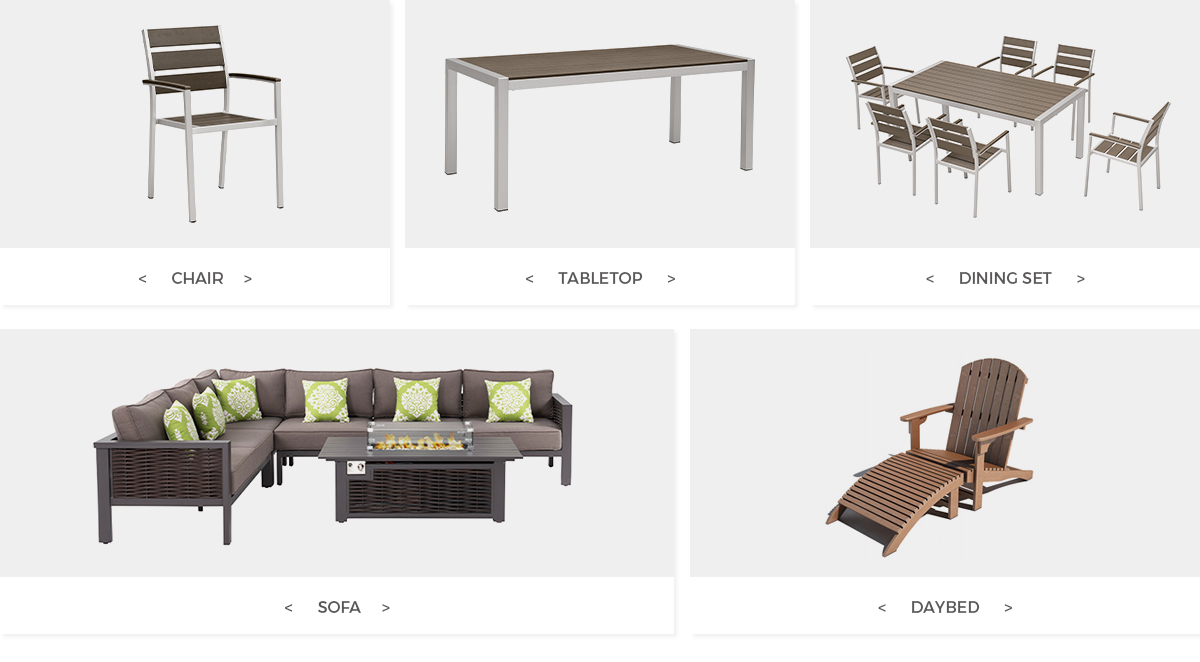

When used in outdoor furniture, plastic wood is usually made into a rectangular, also called plastic wood slat. Sometimes the plastic wood can be molded into round and rhombus, but they are very less popular, particularly used for special purposes. The bearing capacity of plastic wood of different shapes remains almost the same. Plastic wood slat is usually used for upholstering various parts of outdoor furniture like seats, backs, and arms of chairs, benches, tabletops, sofa arms, backs of sun loungers, etc.

What Is Plastic Wood Made of?

Plastic wood is mainly made of high-performance and recyclable polymer and plastic, mostly Polystyrene, standing for PS. To enhance the strength of plastic wood, some auxiliary materials will be added, such as a UV-light agent, anti-aging agent, foaming agent, etc.First of all, mix well the raw material PS with pigment and other ingredients like UV agent, anti-aging agent, and foaming agent in proportion. Then put the mixture into the extrusion machine. The initially formed plastic wood will be extruded at a high temperature through the extruder, and later it will be directly delivered to the cooling bath for cooling. When the semi-finished plastic wood comes out, it will be cut into different lengths by an automatic cutting machine. Then, there will be an embossing process for plastic wood to create the various surface effect. After the finished plastic wood is washed cleanly, it will be packed and sent to the warehouse waiting for shipping. Some clients want their plastic wood to be much more high-strength, so manufacturers like us will add aluminum pipes inside the plastic wood to increase their bearing capacity because aluminum pipes are not easy to rust, light, and easy to process and cut.

Why Is Plastic Wood Suitable For Outdoor Furniture?

Waterproof

Unlike other furniture materials like wood easily rotting away in humid conditions, plastic wood is 100% waterproof. Plastic wood can be used in humid environments for a very long time without perishing and growing mildew and fungus, expanding its service life and protecting your health.Weatherproof

Being an outstanding outdoor furniture material, plastic wood is born with excellent weatherproof performance. It can resist most outdoor elements like rains, UV light, sun heat, snow, etc. That’s why plastic wood furniture is suitable for outdoor uses all year round.Durable

Plastic wood is made of a high-strength polymer called Polystyrene, which makes it much more durable than other furniture materials like solid wood. It won’t crack or fade easily although being placed in outdoor environments all the time. With a non-porous structure, moisture and other outdoor elements can hardly threaten the plastic wood.Eco-logical

Plastic wood slat is an environmental outdoor furniture material because there is no real wood material involved in the manufacturing process. It doesn’t consume and wastes natural resources. Instead, a recyclable and Eco-logical plastic material named polystyrene is mainly utilized in plastic wood.Low-maintenance

Plastic wood is super easy-cleaning and it requires little maintenance. To keep plastic wood slat looking nice, you just need to use a damp cloth to wipe the dust off regularly, no waxing or re-polishing required, saving your money and effort.Safe&Healthy

Plastic wood slat is 100% non-toxic for humans, making it the ideal material for outdoor dining sets. In addition, compared to natural wood material, plastic wood slats won’t suffer from the woodworm, avoiding causing health problems over time.Variety&Customization

Plastic wood is available in a wide range of color, pattern, finish, shape, and size to meet all requirements for outdoor furniture. Besides, you can customize plastic wood as you desire for it is a man-made material.Cost-effective

Plastic wood slat is quite inexpensive on the market of outdoor furniture materials compared to solid wood and composite wood but provides more excellent performance and greater durability.Where to Buy Plastic Wood For Outdoor Furniture?

We are one of the best plastic wood manufacturers in China. With more than 25 years of export experience, we are good at making and delivering high-quality plastic wood for our clients from all over the world.Our Showroom of Plastic Wood

For any outdoor furniture material wholesale or production projects, welcome to contact us at info@leisuretouch-rattan.com. We can ensure the best quality and reasonable price to grow your business.